Magnetic Bars

Model table for Filter Bars

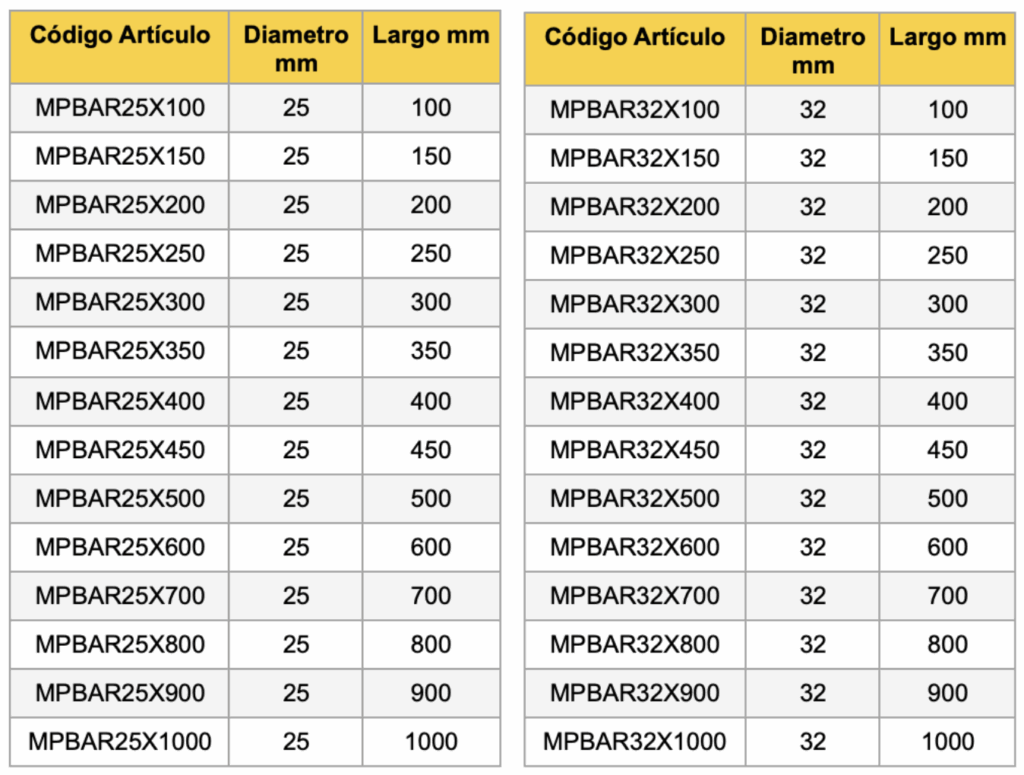

Model table for Filter Bars with Handle

CÓDIGO |

MPBAR25X100 CON MANGO |

MPBAR25X150 CON MANGO |

MPBAR25X200 CON MANGO |

MPBAR25X250 CON MANGO |

MPBAR25X300 CON MANGO |

MPBAR25X400 CON MANGO |

MPBAR25X500 CON MANGO |

|

|

|

CÓDIGO |

|

MPBAR32X100 CON MANGO |

|

MPBAR32X150 CON MANGO |

|

MPBAR32X200 CON MANGO |

|

MPBAR32X300 CON MANGO |

|

MPBAR32X400 CON MANGO |

|

MPBAR32X500 CON MANGO |

Neodymium Magnetic Bars: High Efficiency for Removing Ferromagnetic Contaminants

Introduction: Powerful Magnetic Separation for Clean Production

MagnetPlastic’s Neodymium Magnetic Bars are engineered to deliver high-efficiency separation of ferromagnetic contaminants from product flows. These bars play a crucial role in maintaining quality, safety, and compliance across various sectors—particularly in the food, chemical, and pharmaceutical industries, where even minimal contamination can have serious consequences.

Key Features

1. Advanced Design for Maximum Efficiency

Each bar contains a high-performance multi-pole magnetic circuit that ensures the effective capture of iron particles and other ferrous contaminants—even in challenging conditions such as high-flow systems or fine powders.

2. Durable AISI-316 Stainless Steel Casing

Provides exceptional corrosion resistance, making it suitable for humid and sterile environments.

Complies with international sanitary standards for food and pharma applications.

Ensures extended service life and robust mechanical durability.

3. Versatile Integration with Magnetic Filters and Grids

Neodymium magnetic bars are core components in the assembly of magnetic separators, such as filters, grates, and drawers, enabling tailored solutions for different process configurations.

4. Easy to Install and Maintain

Their compact and streamlined design allows seamless integration into new or existing equipment.

A polished surface finish reduces product buildup and simplifies routine cleaning, supporting hygienic production environments.

Industrial Applications

Food Industry:

Essential for removing metal contaminants from powders, granules, and liquids—enhancing consumer safety and compliance with food safety standards.

Chemical Industry:

Used to ensure product integrity by capturing metallic particles during mixing, drying, or conveying processes.

Pharmaceutical Industry:

Supports the production of pure, contaminant-free medical products, aligning with strict GMP and FDA standards.

Machinery Protection:

Prevents equipment damage by intercepting metal debris before it enters pumps, valves, or processing machinery.

Advantages of MagnetPlastic Neodymium Bars

✅ Product Safety and Quality

Guarantee removal of hazardous ferromagnetic particles, preserving the integrity of the end product and the machinery.

✅ Customizable Design

Available in multiple sizes, shapes, and strengths, adaptable to custom production line requirements.

✅ Sustainable and Efficient

Improve overall production by reducing waste, minimizing downtime, and cutting maintenance costs.

✅ Regulatory Compliance

Designed to comply with IFS, BRC, HACCP, and other international standards in critical industries.

The MagnetPlastic Commitment

At MagnetPlastic, we deliver precision-engineered magnetic solutions trusted by industry leaders. Our Neodymium Magnetic Bars are a smart investment in your facility’s safety, performance, and operational excellence.

If you are looking to upgrade your magnetic separation systems, improve product purity, or protect your industrial equipment, contact us today. Our team of experts will help you design a custom magnetic solution tailored to your unique process needs.

Neodymium Magnetic Bars: High Efficiency for Removing Ferromagnetic Contaminants

Introduction: Powerful Magnetic Separation for Clean Production

MagnetPlastic’s Neodymium Magnetic Bars are engineered to deliver high-efficiency separation of ferromagnetic contaminants from product flows. These bars play a crucial role in maintaining quality, safety, and compliance across various sectors—particularly in the food, chemical, and pharmaceutical industries, where even minimal contamination can have serious consequences.

Key Features

1. Advanced Design for Maximum Efficiency

Each bar contains a high-performance multi-pole magnetic circuit that ensures the effective capture of iron particles and other ferrous contaminants—even in challenging conditions such as high-flow systems or fine powders.

2. Durable AISI-316 Stainless Steel Casing

Provides exceptional corrosion resistance, making it suitable for humid and sterile environments.

Complies with international sanitary standards for food and pharma applications.

Ensures extended service life and robust mechanical durability.

3. Versatile Integration with Magnetic Filters and Grids

Neodymium magnetic bars are core components in the assembly of magnetic separators, such as filters, grates, and drawers, enabling tailored solutions for different process configurations.

4. Easy to Install and Maintain

Their compact and streamlined design allows seamless integration into new or existing equipment.

A polished surface finish reduces product buildup and simplifies routine cleaning, supporting hygienic production environments.

Industrial Applications

Food Industry:

Essential for removing metal contaminants from powders, granules, and liquids—enhancing consumer safety and compliance with food safety standards.

Chemical Industry:

Used to ensure product integrity by capturing metallic particles during mixing, drying, or conveying processes.

Pharmaceutical Industry:

Supports the production of pure, contaminant-free medical products, aligning with strict GMP and FDA standards.

Machinery Protection:

Prevents equipment damage by intercepting metal debris before it enters pumps, valves, or processing machinery.

Advantages of MagnetPlastic Neodymium Bars

✅ Product Safety and Quality

Guarantee removal of hazardous ferromagnetic particles, preserving the integrity of the end product and the machinery.

✅ Customizable Design

Available in multiple sizes, shapes, and strengths, adaptable to custom production line requirements.

✅ Sustainable and Efficient

Improve overall production by reducing waste, minimizing downtime, and cutting maintenance costs.

✅ Regulatory Compliance

Designed to comply with IFS, BRC, HACCP, and other international standards in critical industries.

The MagnetPlastic Commitment

At MagnetPlastic, we deliver precision-engineered magnetic solutions trusted by industry leaders. Our Neodymium Magnetic Bars are a smart investment in your facility’s safety, performance, and operational excellence.

If you are looking to upgrade your magnetic separation systems, improve product purity, or protect your industrial equipment, contact us today. Our team of experts will help you design a custom magnetic solution tailored to your unique process needs.

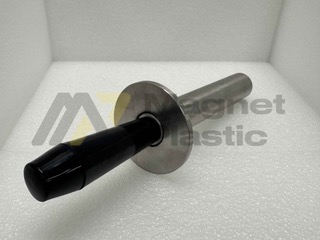

Neodymium Magnetic Bars with Handle: Practical and Efficient Removal of Ferromagnetic Contaminants

Introduction: Precision Separation with Comfortable Handling

Neodymium Magnetic Bars with Handle from MagnetPlastic are engineered to offer powerful magnetic separation while providing convenient manual operation. These bars are essential in industries where product purity, safety, and regulatory compliance are priorities—especially in the food, chemical, and pharmaceutical sectors.

For added hygiene and durability, these bars can also be supplied with an AISI-316 stainless steel sleeve, simplifying the cleaning process.

Key Features

1. Advanced Design and High Efficiency

Equipped with a comfortable handle, these bars allow operators to manually extract ferrous contaminants with high accuracy, even in demanding environments such as powder processing or liquid flow systems.

2. AISI-316 Stainless Steel Cladding

Provides exceptional corrosion resistance, perfect for humid or sanitary environments.

Complies with stringent hygiene standards in food and pharmaceutical industries.

Ensures a long service life and minimal wear during repeated use.

3. Easy to Use and Maintain

The compact and ergonomic design allows for easy handling and integration into existing production processes.

A polished surface prevents material buildup, making the cleaning process faster and maintaining a safe, hygienic workspace.

Industrial Applications

These Neodymium Magnetic Bars with Handle are versatile and find applications in a wide range of sectors:

🟢 Food Industry

Capture and remove metal particles from granulated goods, powders, and liquids, safeguarding product safety and preventing equipment damage.

🟠 Chemical Industry

Ensure the consistency and purity of chemical compounds by removing fine ferrous particles during production.

🔵 Pharmaceutical Industry

Maintain the highest standards of product purity by eliminating metallic contaminants during the processing of drugs and medical formulations.

Advantages of MagnetPlastic Handheld Magnetic Bars

✅ Precision Handling

The integrated handle allows for manual inspection and contamination removal in specific zones—ideal for spot-checks or cleaning smaller batches.

✅ Hygienic and Compliant

Stainless steel versions meet HACCP, IFS, and other international standards for sanitary production environments.

✅ Durability and Performance

Designed for daily industrial use, these magnetic bars withstand exposure to moisture, chemicals, and wear without losing effectiveness.

✅ Operator-Friendly

The handle enhances ergonomics and ease of operation, reducing strain and allowing quick deployment in various processing areas.

Why Choose MagnetPlastic?

At MagnetPlastic, we develop tailored magnetic solutions for every stage of production. Our Neodymium Magnetic Bars with Handle provide a reliable, easy-to-use tool for maintaining clean production lines and preventing contamination.

If your process demands precision magnetic separation, especially in high-risk industries, these bars are a smart addition to your quality control strategy.

📩 Contact us today to explore models, sizes, and customization options. Our team of specialists will help you implement the best magnetic solution for your operation.

We answer in 24/48 hours

Contact us

If you need information or advice for any type of magnetic application, fill out the following form.

We will contact you within 48 hours.