Magnetic Plates

• The MPPM magnetic plates are used in low-flow productions where there is no significant contamination of ferromagnetic metals, extracting and retaining them on their surfaces.

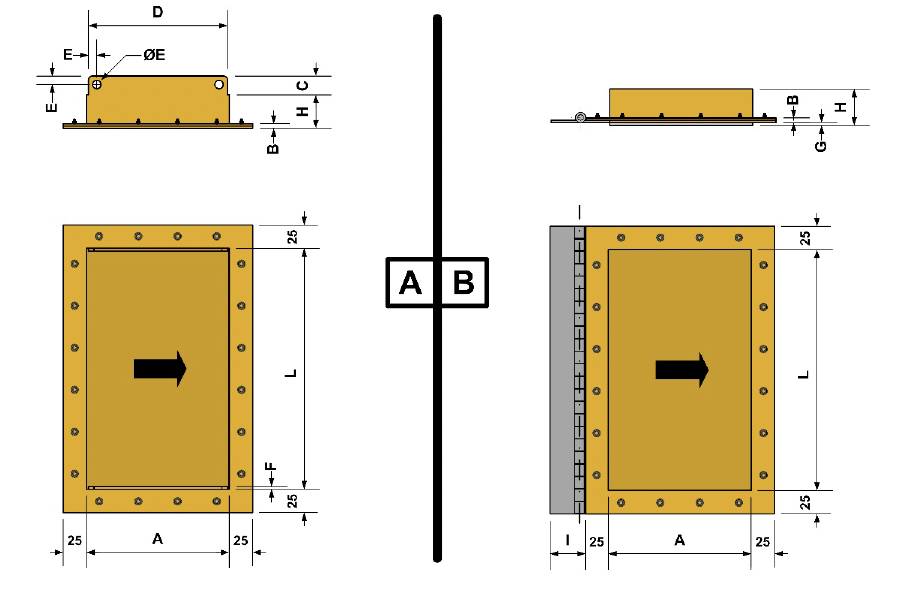

• They are typically positioned on the exterior of screw conveyors, chutes, or closed ducts where products flow by drag, free fall, or under certain pressure. For these applications, the magnetic attraction zone is always positioned a few millimeters inside the duct system. The magnetic plate bases are manufactured with a smooth finish but can be supplied with one or two non-slip protrusions, either flat or inclined, to prevent small attracted ferromagnetic metals from being carried away by the production flow. In such cases, the magnetic plates are provided with a hinge for easy access to the retained ferrous metals.

• Magnetic plates can also be placed transversely over conveyor belts or longitudinally along the drop of products from the belts. In these scenarios, the units are equipped with two perforated side flanges to allow for easy mounting or suspension wherever needed.

• They feature an external square or rectangular chassis housing a ferrite or neodymium magnetic core that generates a powerful, constant, and intense magnetic field.

• High extraction capacity for both small and large ferromagnetic metals.

• Sturdy, reliable, and easy to install. They do not require electrical connections and have no mechanical maintenance needs.

• The separation of retained ferromagnetic metals on the equipment’s bases is usually done manually using appropriate protective gloves.

• These units are ideal for use alongside metal detectors to ensure maximum reliability in the extraction or detection of both ferrous and non-ferrous metals.

• The chassis are usually industrially painted in our corporate color, but they can be supplied in any other required color.

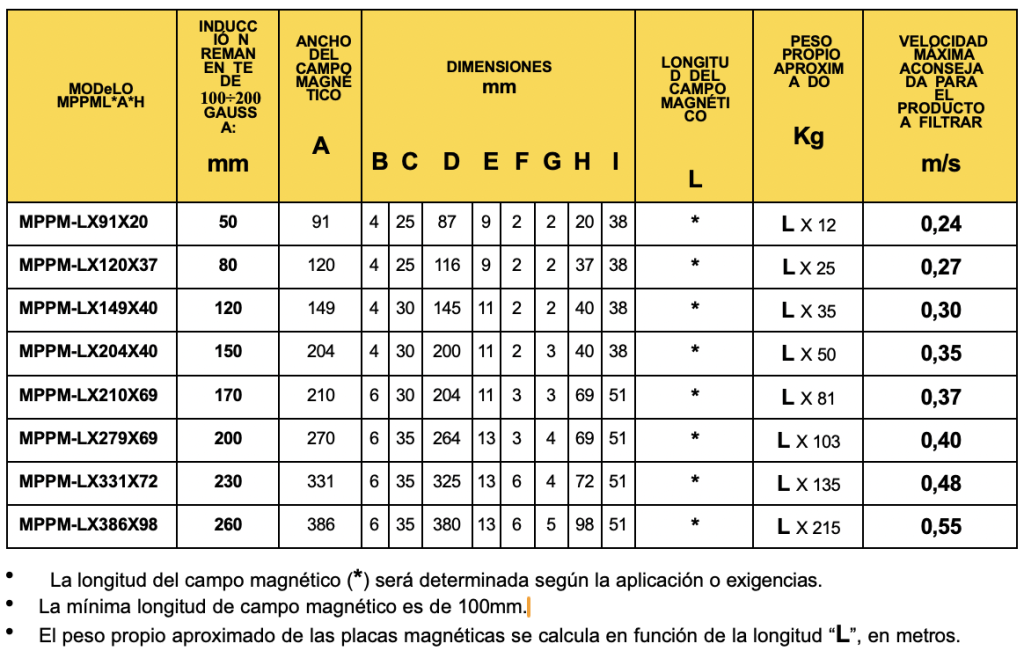

• Available in different models depending on production needs and the required level of ferromagnetic extraction.

• Typically purchased by industries processing fine granulated products with low moisture content, such as food, glass, plastic, wood, aggregates, or mining.

• Supplied on demand.

• Designed and manufactured by our company.

• One-year warranty against any manufacturing defects.

• CE compliance certificates according to current directives and regulations.

• Optimal operating temperature: -10ºC to 80ºC.

• Protection rating: IP65.

• The equipment can be supplied with side flanges (A) or hinges (B) for suspension or mounting.

We answer in 24/48 hours

Contact us

If you need information or advice for any type of magnetic application, please fill in the following form.

We will contact you within 48 hours.