All About Magnetic Filtration and Magnetic Separation

Magnetic filtration is an essential technology in industries that need to remove ferrous contaminants from bulk materials, ensuring both product purity and equipment protection. Magnetic filtration systems offer a wide range of advantages that make them a key tool for improving product quality, safeguarding processing equipment, and reducing maintenance costs.

Why Use Magnetic Filtration?

1. Protection of Engines and Machinery

By eliminating ferrous particles that traditional filters might miss, magnetic filtration helps prevent damage to critical engine components such as bearings, pistons, and valves. This extends the operational life of engines and industrial machines.

2. Cost Savings

Preventing machinery wear reduces downtime and prolongs equipment lifespan. Magnetic filtration systems help significantly cut long-term maintenance costs, making them a cost-effective solution for both small- and large-scale operations.

3. Environmental Benefits

Using magnetic filtration to extend machinery life and ensure contaminant-free products benefits both the environment and industry by reducing industrial waste and improving sustainability.

Industries That Use Magnetic Filtration

Automotive Industry:

Magnetic filtration plays a key role in protecting engines, automatic transmissions, and power steering systems by removing ferrous particles from oil, ensuring optimal performance, especially in high-performance and racing engines.

Industrial Machinery:

In sectors like manufacturing, mining, and agriculture, heavy equipment operates under harsh conditions and is vulnerable to metallic debris. Magnetic filtration protects hydraulic and lubrication systems, keeping machinery efficient and functional.

Aerospace Industry:

In aviation, where system reliability is crucial for safety, magnetic filtration is used to remove ferrous contaminants from engine oils. This helps maintain engine reliability and reduces the risk of failure during operation.

Oil and Gas Industry:

Magnetic filtration is widely used to remove metal particles from drilling fluids and lubricants, protecting critical components on drilling rigs, reducing wear, and extending overall equipment life.

Food and Beverage Industry:

Magnetic filtration ensures that liquids in contact with food are free of metal particles, maintaining hygiene standards and ensuring food safety in compliance with health regulations.

Main Types of Magnetic Filtration

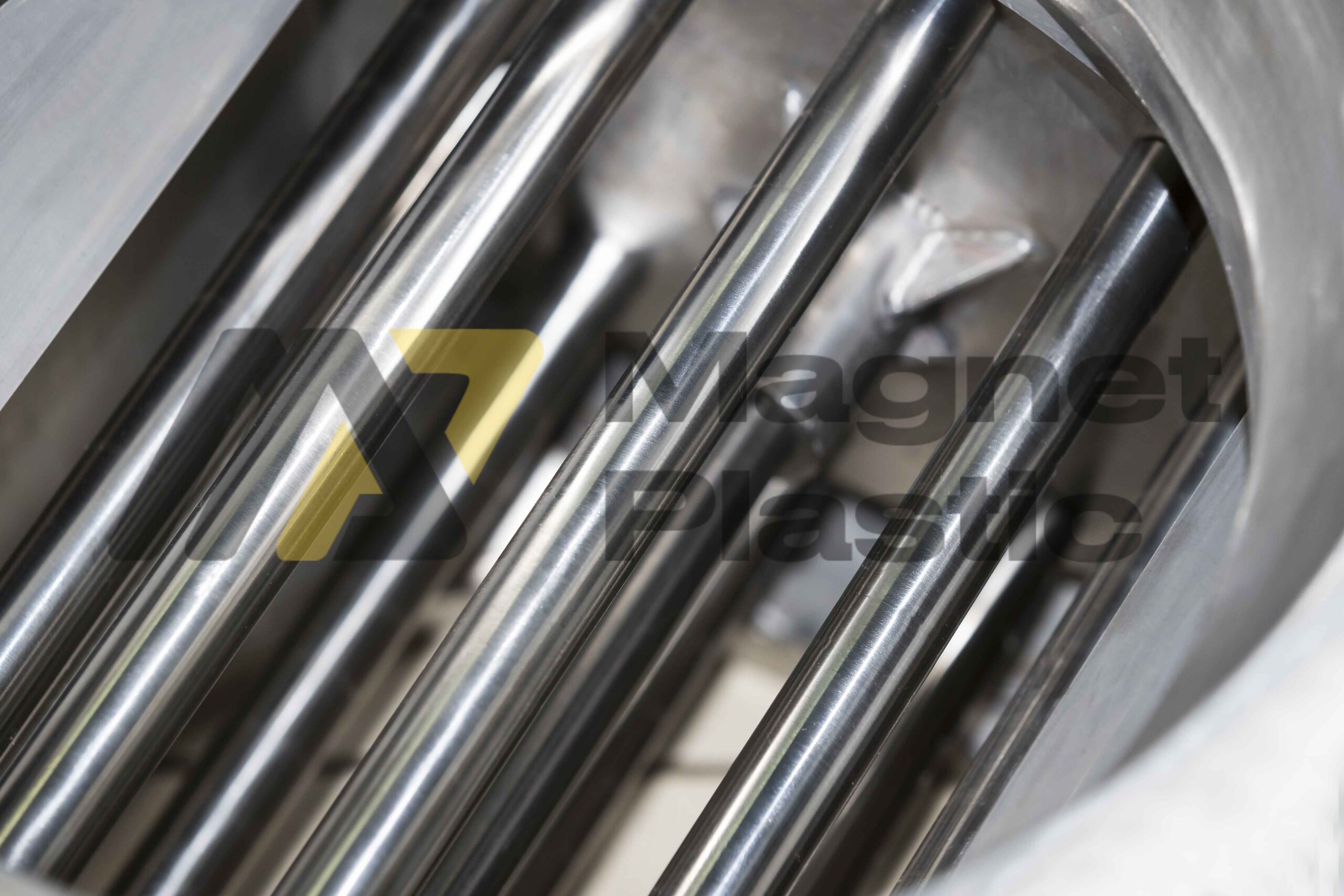

Round Magnetic Grid:

A circular magnetic separator designed to capture ferrous contaminants from materials flowing through pipes or hoppers. It contains an array of magnetic rods arranged in a circular configuration, ensuring product purity and equipment protection.

Square Magnetic Grid:

Works similarly to the round version but with a square configuration of magnetic bars. Ideal for use in rectangular containers, chutes, and hoppers for bulk material processing.

Magnetic Pulley:

A magnetic separator integrated into the head or end of a conveyor system. As materials pass over the pulley, ferrous contaminants are attracted to its surface while non-ferrous materials continue to flow freely. Widely used in continuous metal separation in bulk handling systems.

Magnetic Bars:

Typically used in magnetic separator frames, these bars effectively remove iron impurities and small metallic particles from loose or flowing raw materials.

Conclusion

Magnetic filtration is a powerful technology that significantly enhances cleanliness, extends equipment life, and boosts process efficiency. By capturing ferrous particles that conventional filters may overlook, magnetic filters provide essential protection for all types of machinery.

From automotive engines to food processing lines, magnetic filtration systems—like those developed by MagnetPlastic—are engineered to meet industry-specific needs, ensuring optimal performance, lower maintenance costs, and increased equipment longevity.