Applications of Magnets in Modern Industry

1. An Essential Component in Industrial Innovation

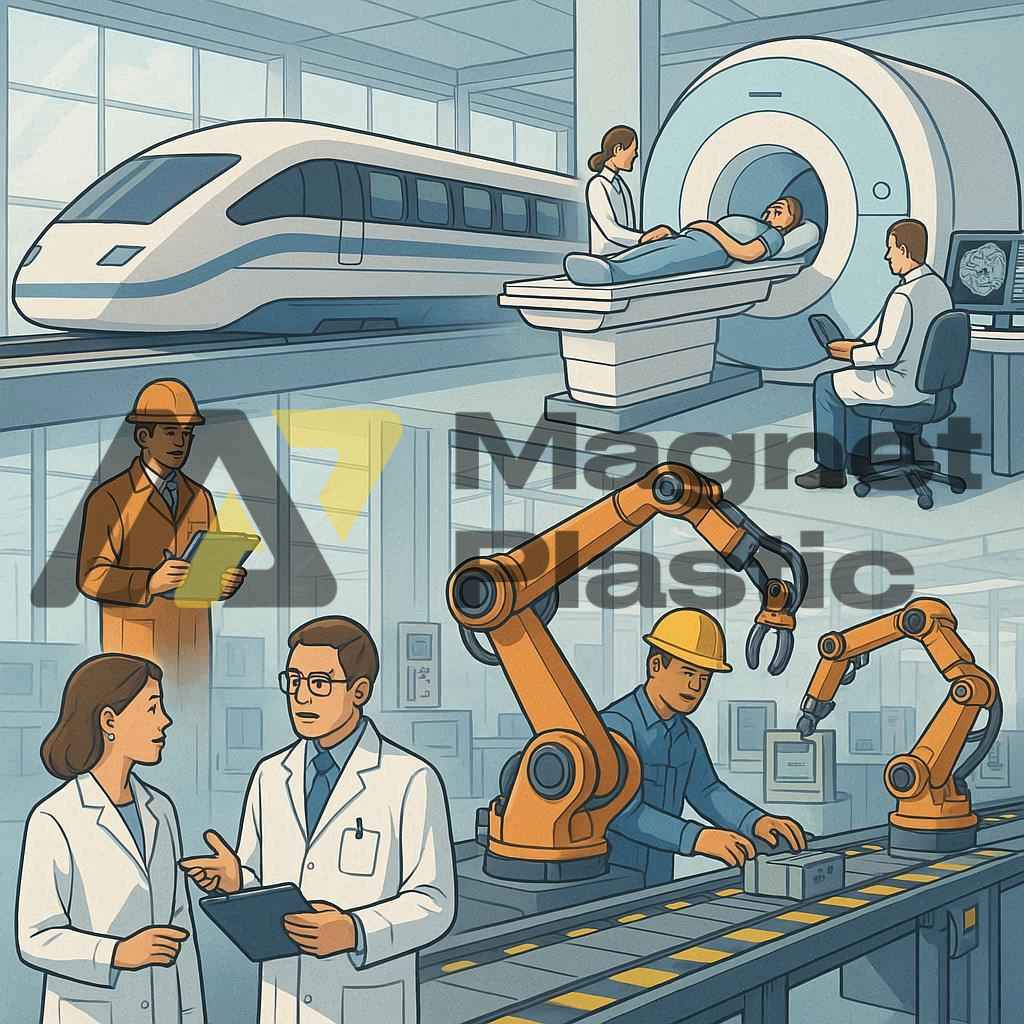

Magnets are key components in numerous industrial sectors due to their ability to attract, separate, detect, or generate movement. Their use goes far beyond what might seem apparent: they enable process automation, optimize production, transport loads, generate energy, and ensure safety in electrical and mechanical systems. Thanks to their versatility, magnets are present in almost every area of modern technology and manufacturing.

2. Variety of Materials and Designs

Depending on their composition and manufacturing process, magnets can come in different shapes, sizes, and strengths. At Magnetplastic, the R&D and engineering team develops magnetic solutions tailored to each industrial need, ranging from high-power neodymium magnets to adjustable electromagnetic systems for more complex processes.

3. Applications by Industrial Sector

Automotive

Magnets are indispensable in the operation of electric motors, sensors, brakes, and safety systems in modern vehicles. Ferrite magnets are commonly used in motors, while the more powerful neodymium magnets are increasingly used in electric vehicles due to their ability to generate greater energy efficiency.

Construction

In this sector, magnets facilitate the transport of heavy materials and temporary fixing on metal structures or formworks. They are also used in tools, signage, and quick assembly systems, improving safety and productivity on construction sites.

Logistics and Packaging

The rise of e-commerce has driven the use of magnetic solutions in conveyor belts, smart labels, magnetic bases, and closure systems, optimizing the storage and transportation of goods.

Recycling

Magnets are essential for separating metallic materials and removing contaminants during sorting processes. Magnetic separators detect and remove ferrous particles, ensuring the purity of recycled material and protecting machinery from potential damage.

Food Industry

In this sector, magnets guarantee the purity and safety of the final product. Magnetic separation systems remove metallic impurities before packaging, complying with the highest hygiene and quality standards.

Robotics and Material Handling

Magnets are used in sensors, linear motors, robotic arms, automatic doors, and medical devices such as radiology or dialysis equipment. Magnetic innovation has enabled the development of more precise, safe, and sustainable applications.

Mining

In extraction processes, magnetic belts and electromagnets remove ferrous materials that could damage equipment, improving both efficiency and safety.

Plastics Industry

During injection molding or the production of plastic parts, magnets remove metal fragments or contaminants, ensuring high-quality final products and reducing downtime.

4. Most Common Types of Magnets

- Neodymium: The most powerful, ideal for small spaces; can withstand up to 200 °C.

- Ferrite or Ceramic: More economical, with good thermal resistance (up to 250 °C).

- Alnico: High magnetic stability and resistance to temperatures up to 450 °C.

- Electromagnets: Generate electrically controlled magnetic fields; some models combine the properties of permanent magnets.

5. Conclusion

Magnets are a silent yet indispensable tool in modern industry. At Magnetplastic, with over 20 years of experience, customized magnetic solutions are developed to optimize processes, ensure quality, and promote technological innovation in key sectors of the global economy.