Choosing the Perfect Magnet – Magnetplastic Guide

Choosing the right magnet can make or break a technical, industrial, or creative project. A magnet that is too weak, poorly sized, or made from an unsuitable material can compromise the final outcome. At Magnetplastic, we help companies identify the ideal magnetic solution through our technical expertise, in-house laboratory, and advanced measuring equipment. Our goal is to ensure each client finds the magnet perfectly adapted to their needs.

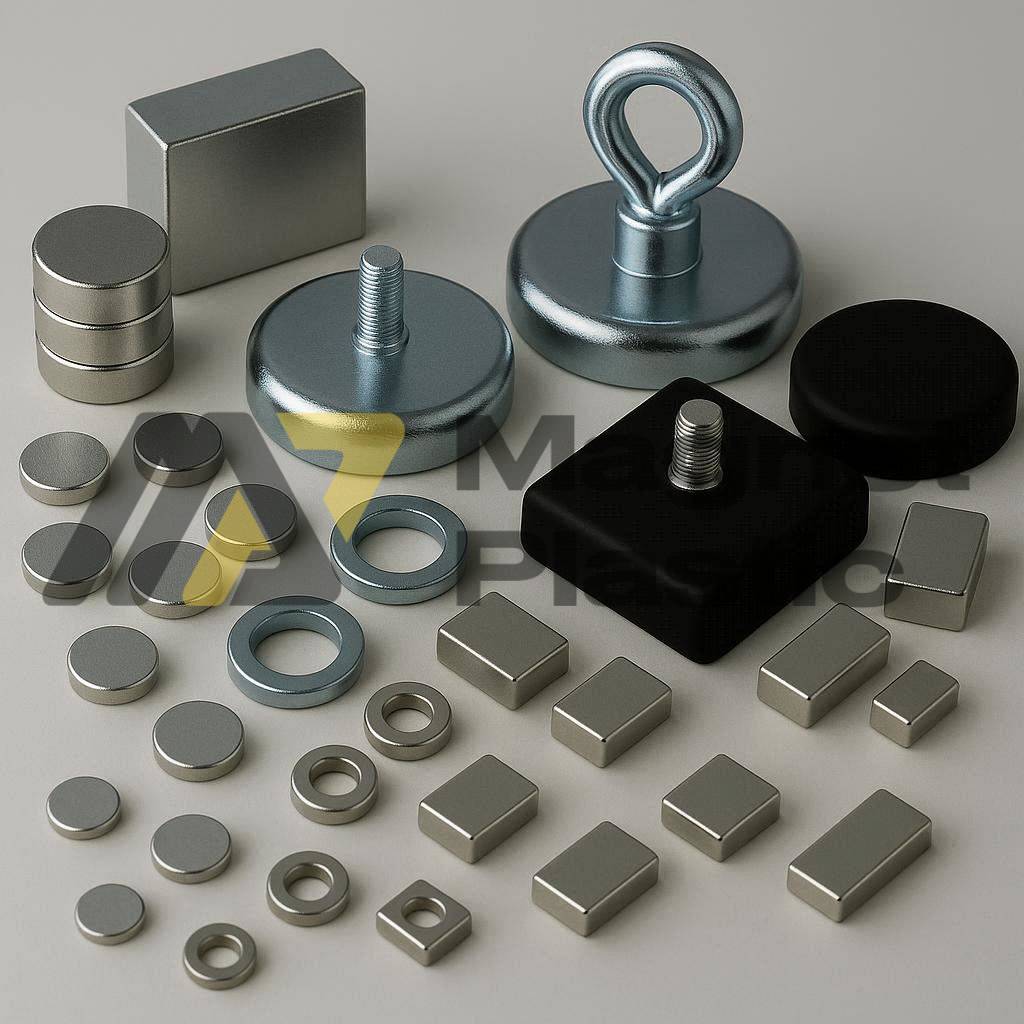

Magnet Types

The world of magnets is diverse, and each type offers specific characteristics for different uses.

Neodymium

The strongest magnets available. Ideal for high-performance needs in limited space—used in industrial systems, precision tools, technology, and demanding fastening mechanisms.

Ferrite

Affordable and naturally corrosion-resistant. Suitable for decoration, signage, and applications that do not require extreme magnetic force. Robust and stable for low- to medium-intensity uses.

Flexible Magnets

Made of PVC or rubber. Versatile, safe, and easy to shape. Ideal for crafts, DIY, education, signage, and creative projects.

Key Factors

Before choosing a magnet, it’s essential to assess several technical points:

Strength

Depends on material, size, and shape. A mismatched magnet may provide too little or too much force.

Temperature

Some magnets, especially neodymium, lose strength at high temperatures. Knowing the operating environment is crucial.

Corrosion Resistance

Ferrite is naturally resistant, while neodymium typically requires protective coatings to prevent oxidation.

Shape & Size

Discs, blocks, rings, and bars each serve different functional needs depending on the project.

How Magnetplastic Helps

Magnetplastic provides more than just magnets—we deliver complete magnetic solutions tailored to each project. With our in-house laboratory and specialized control equipment, we can:

- Test magnetic quality and strength

- Measure precise magnet performance

- Offer personalized technical advice for optimal selection and integration

Our experts work closely with every client to ensure the chosen magnet meets all safety, durability, and efficiency requirements.

Applications

Neodymium: Tool holding, motors, industrial mechanisms, sensors, precision devices.

Ferrite: Magnetic displays, signage, promotional items, low-load magnetic components.

Flexible: Magnetic boards, DIY, school projects, flexible signage, creative designs.

Conclusion

Selecting the right magnet becomes simple when the project’s needs—strength, size, shape, and environment—are clearly defined. With Magnetplastic’s expert guidance, specialized laboratory, and advanced measurement tools, you can be confident that your project will have the perfect magnetic solution, ensuring durable, reliable, and efficient results.