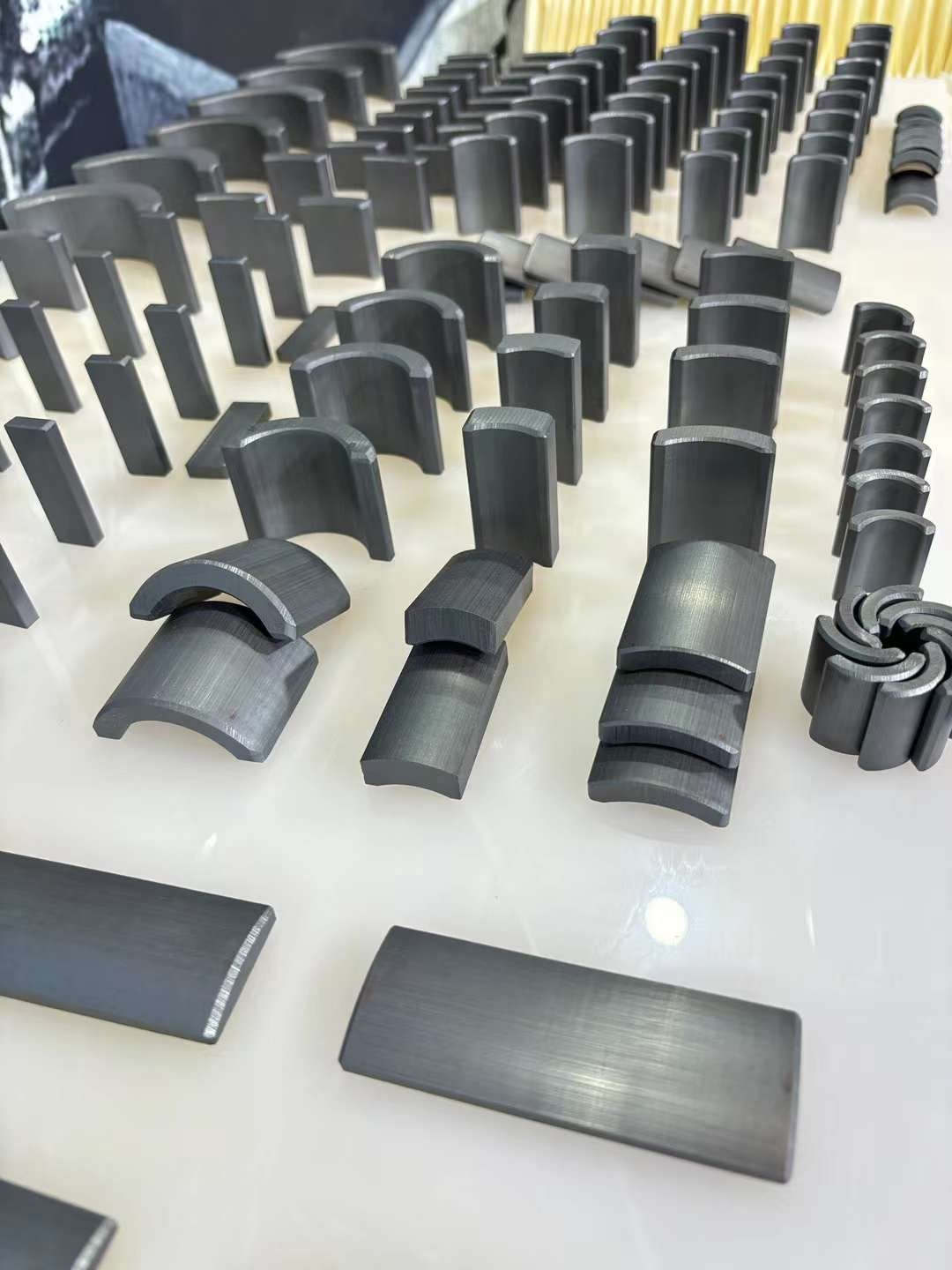

Ferrite Magnets: Manufacturing, Properties, and Industrial Applications

Ferrite magnets, also known as ceramic magnets, are widely used in modern industry due to their excellent balance of magnetic performance, thermal stability, and cost-effectiveness. Made primarily from iron oxide (Fe₂O₃) combined with strontium carbonate (SrCO₃) or barium carbonate (BaCO₃), these permanent magnets are known for their high resistance to demagnetization and reliable performance at elevated temperatures.

Manufacturing Process

The production of ferrite magnets involves several key stages that ensure the final product’s quality and performance:

1. Mixing and Milling:

Raw materials are carefully selected, measured, and finely ground into a homogeneous powder. The fineness of this powder—often down to submicron levels—is critical to achieving consistent quality in the final product.

2. Forming:

The fine powder is compressed into molds under high pressure. This forming process can be done in either dry or wet conditions, depending on the type of ferrite magnet being produced. Magnetic fields may also be applied to align the particles, enhancing the magnetic properties of the final product.

3. Sintering:

The formed parts are heated in specialized kilns at temperatures ranging from 1,000°C to 1,300°C. Sintering causes the particles to bond and form a dense, solid structure. Interestingly, the parts shrink significantly during this process, and this is accounted for in the design stage.

4. Cooling and Machining:

After sintering, the magnets are gradually cooled to prevent internal stresses and cracking. They may then undergo machining (cutting, drilling, grinding) to achieve precise shapes and dimensions tailored to their final application.

5. Magnetization:

In the final step, the sintered and machined pieces are exposed to a strong magnetic field that imparts their permanent magnetic properties. This magnetization process is performed using specialized equipment tailored to the desired magnetic characteristics.

Operating Temperature Range

Ferrite magnets can operate effectively within a wide temperature range:

- Minimum operating temperature: Around -20°C.

- Maximum operating temperature: Typically 250°C to 300°C (482°F to 572°F). Beyond this, their magnetic strength begins to degrade.

The exact limits may vary depending on the grade, composition, and manufacturing method.

Advantages of Ferrite Magnets

- Cost-effective: Among the most affordable permanent magnets, ideal for mass production.

- High resistance to demagnetization: Reliable in environments exposed to external magnetic fields.

- High electrical resistivity: Reduces eddy current losses, making them suitable for motors and transformers.

- Thermal stability: Maintains magnetic performance at higher temperatures.

Conclusion

Thanks to their efficient manufacturing process, thermal stability, and low cost, ferrite magnets remain an essential component in a wide variety of industrial applications. From electric motors to sensors and household electronics, their reliability and versatility make them a smart choice for magnetic engineering.