Injection-Molded Magnets: Innovation and Versatility in Industry

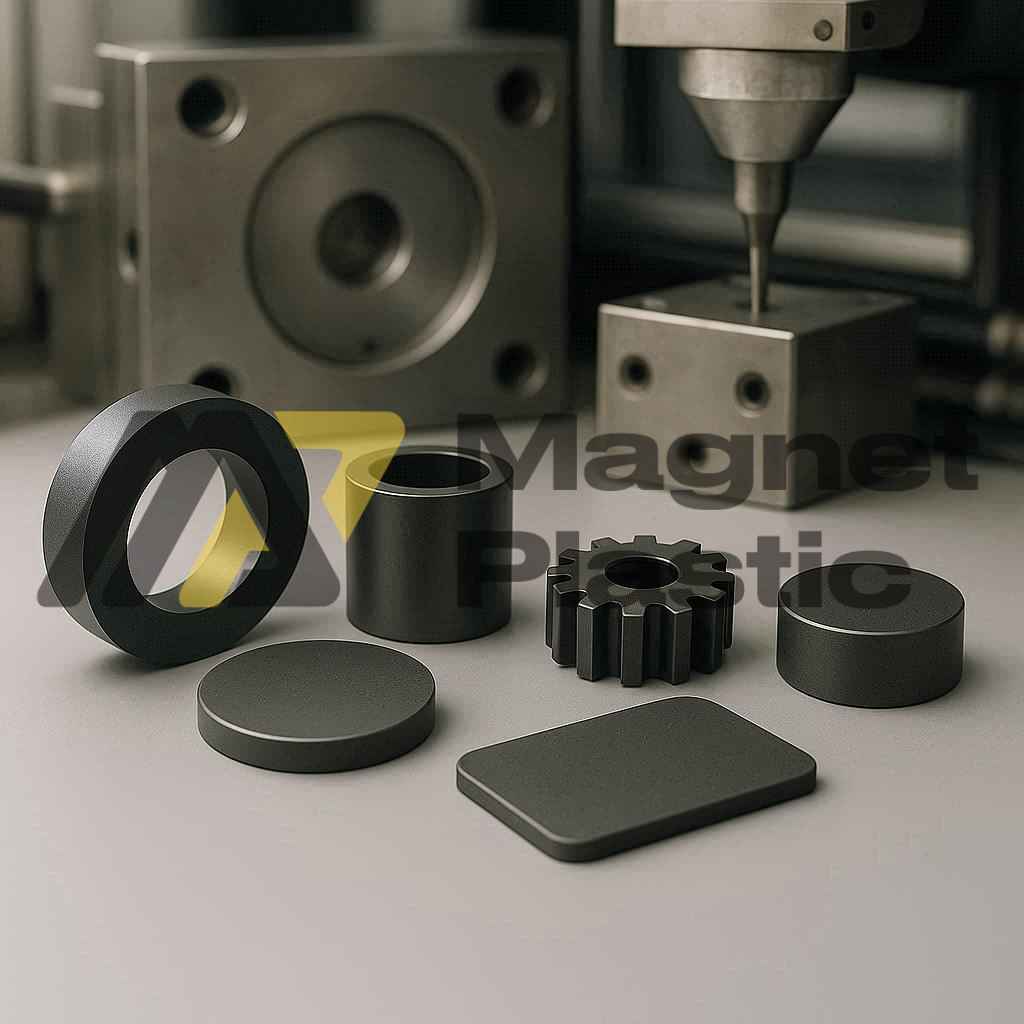

Injection-molded magnets represent a major technological advancement in the production of magnetic components. These materials are created by combining magnetic powders – such as ferrite, neodymium-iron-boron (NdFeB), and samarium-cobalt (SmCo) – with a polymer binder, typically PPS (polyphenylene sulfide) or other engineering plastics. The result is a hybrid material that can be injection molded or extruded just like conventional plastics.

This process allows the manufacturing of parts with very high dimensional accuracy, great design flexibility, and the ability to integrate the magnet directly onto existing components, such as shafts or bushings. This often eliminates the need for gluing or secondary assembly.

Advantages over Sintered Magnets

Compared to traditional sintered magnets, injection-molded magnets offer numerous advantages:

- Improved mechanical strength: less prone to cracking or chipping.

- Dimensional precision: no secondary machining required.

- Design flexibility: enables complex shapes, thin walls, inserts, or overmolding.

- Environmental resistance: withstand high temperatures, humidity, and corrosive agents.

- Magnetic durability: high resistance to demagnetization and long-term stability.

These properties make them ideal for applications where space, shape, and reliability are critical.

Customization and Materials

Injection-molded magnets can be produced with different magnetic powders, depending on the requirements of each application:

- Ferrite: cost-effective and stable in corrosive environments.

- NdFeB (neodymium): maximum magnetic strength in compact dimensions.

- SmCo (samarium-cobalt): excellent performance at high temperatures.

The polymer matrix also allows for the addition of specific properties, such as chemical resistance, lightweight design, or thermal stability, further expanding their range of applications.

Industrial Applications

The versatility of injection-molded magnets is reflected in the wide range of industries where they are used:

- Electric motors: provide constant magnetic fields to power both heavy machinery and small devices like fans or power tools.

- Automation and sensors: switches, actuators, and control systems that rely on magnetic precision.

- Electronics and audio: sound systems, mobile devices, and cooling technologies.

- Medical field: magnetic resonance imaging, biomedical sensors, and magnetic therapy.

- Automotive and robotics: lightweight, durable, and customized components that enhance efficiency and reliability.

Because they can be mass-produced at relatively low cost, injection-molded magnets offer an attractive and competitive solution compared to more traditional magnetic technologies.

The Future of Injection-Molded Magnets

Demand for this technology is rapidly growing, driven by the need for compact, efficient, and durable products. With the expansion of sectors such as electromobility, industrial automation, and medical devices, injection-molded magnets are expected to play an increasingly central role.

Conclusion

Injection-molded magnets are not merely an alternative to conventional magnets; they are an advanced and versatile solution that combines the strengths of traditional magnetic materials with the innovation of polymer technology. Thanks to their customization, durability, and cost-efficient production, they are becoming essential components in modern industry and will continue to shape the future of advanced technology.