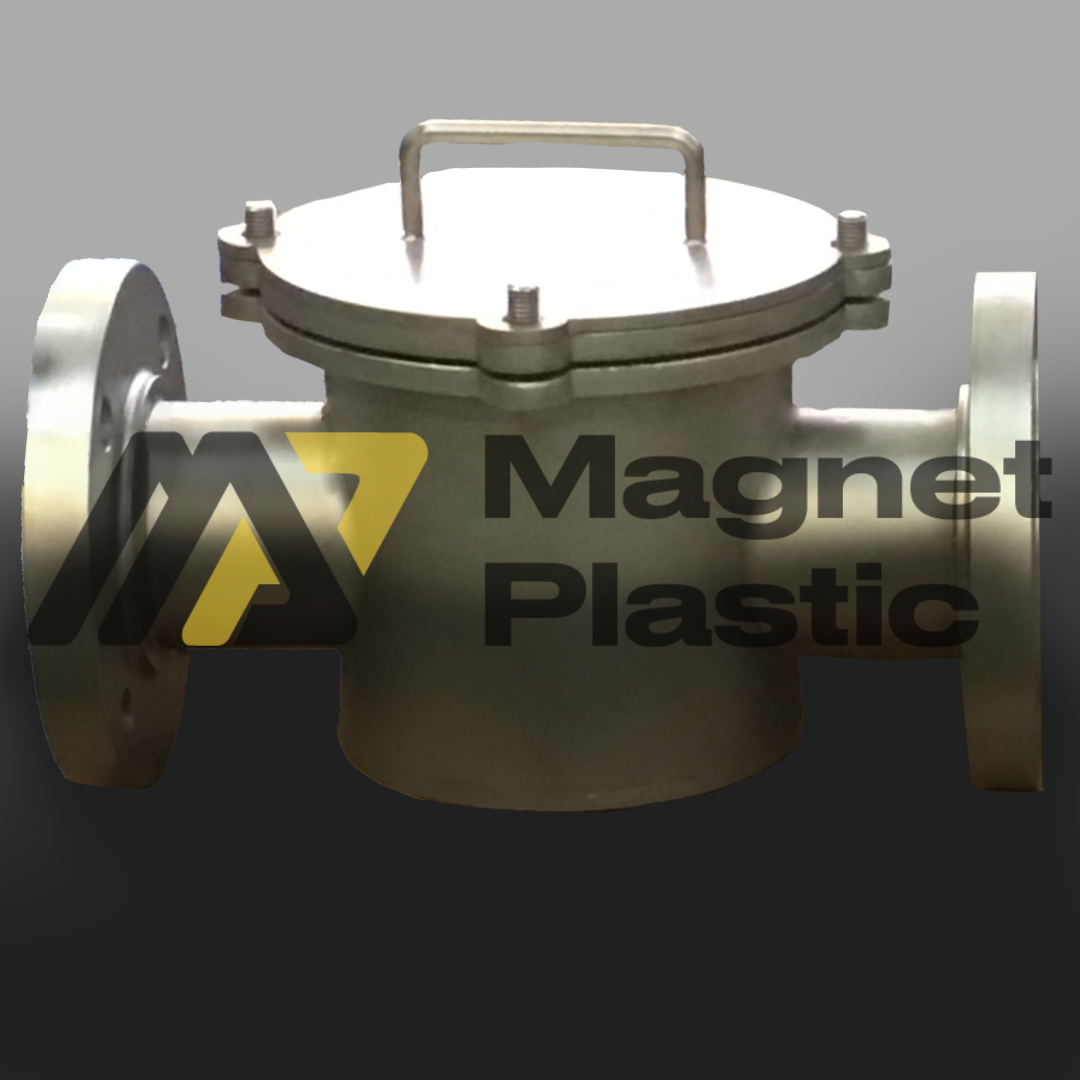

Magnetic Filters for Liquids: Efficient Filtration

In the world of liquid filtration, the application of magnets has emerged as an innovative technology that significantly improves the efficiency and quality of the process. These magnets, strategically incorporated into filtration systems, play a key role in removing magnetic particles and ferrous contaminants. In this article, we will explore the use of magnets in liquid filters, highlighting how they work and the effectiveness of this innovative approach.

Fundamental Operation

Magnets applied in liquid filters take advantage of the magnetic property of certain contaminants in the fluid, such as ferrous particles and magnetic particles. These magnets, usually strategically placed within the filtration system, generate a magnetic field that attracts and retains the ferrous particles present in the moving liquid.

Elimination of Ferrous Contaminants

One of the main benefits of magnets in liquid filters is the ability to efficiently remove ferrous contaminants. These may include rust particles, metal shavings or other ferromagnetic residues present in industrial liquids, lubricants and oils. Magnetic attraction ensures that these particles adhere to the magnet, preventing their circulation and potential damage to equipment or systems.

Improved Filtering Efficiency

Incorporating magnets into liquid filters not only focuses on the removal of ferrous contaminants, but also improves the overall efficiency of the filtration process. By preventing the buildup of magnetic particles on critical components, filter performance is optimized and the life of the filter elements is extended.

Applications in Various Industries

Magnets in liquid filters find applications in a variety of industries, from manufacturing to food and processing industries. In refrigeration systems, hydraulic systems, and industrial machinery, these magnetic filters are essential to maintain the purity of the circulating liquid and ensure trouble-free operation of the equipment.

Reduced Equipment Wear

The presence of ferrous particles in liquids can be harmful to equipment and machinery. Magnets in filters help reduce wear and tear on critical components by trapping and removing particles that could otherwise cause damage. This results in increased reliability and a decrease in costs associated with repair and replacement of parts.

Design and Maintenance Considerations

The effectiveness of magnets in liquid filters depends largely on proper system design and regular maintenance. It is essential to perform regular inspections to ensure that the magnets are clean and working properly. Additionally, the filter design must ensure adequate flow to maximize magnetic particle capture.

In summary, the application of magnets in liquid filters represents a valuable innovation in improving the quality of industrial processes. From removing ferrous contaminants to optimizing filter performance, this magnetic technology proves essential in various applications, contributing to more efficient and reliable operation in a variety of industries.