Magnetic Levitation: Revolution in Transportation and Industry

Magnetic levitation, also known by its acronym Maglev, is a method by which an object is kept afloat by the action of a magnetic field generated by magnets. In other words, magnetic pressure counteracts gravity, allowing the object to levitate without contact with any physical surface.

Applications of Magnetic Levitation

The most common applications of magnetic levitation include:

Maglev Trains: Used in high-speed transportation systems.

Magnetic Bearings: Reduce mechanical wear on industrial machinery.

Magnetic Braking: Deceleration systems in trains and other vehicles.

Levitation of Products for Display: Commercial and marketing applications.

Plasma Levitation in Nuclear Fusion: A possible application in the future if nuclear fusion can be controlled.

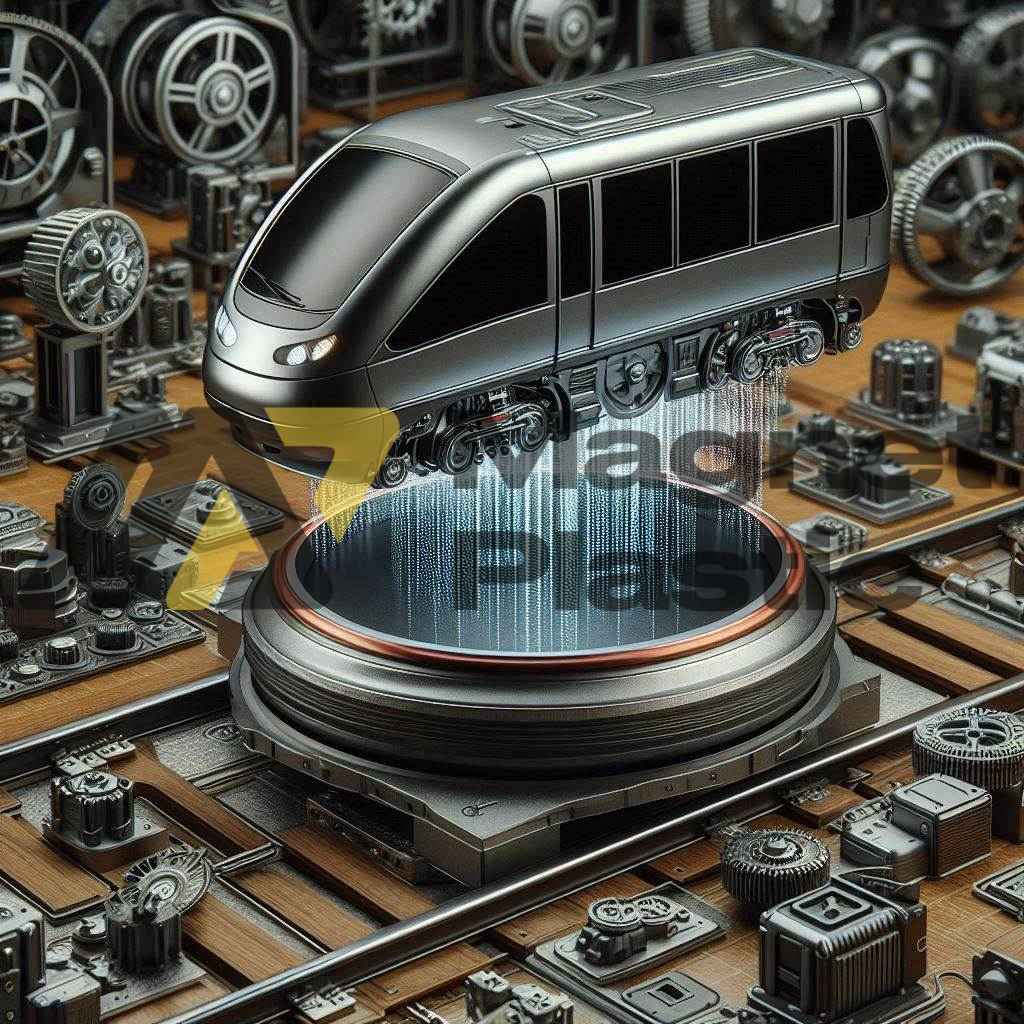

Maglev Trains: Innovation in Transportation

One of the most notable applications of magnetic levitation in transportation is the development of Maglev trains. These trains use powerful magnets to levitate and move along a track, eliminating direct contact with the rails and reducing friction.

Benefits of Maglev Trains

Elimination of Friction: By floating on a magnetic mat, these trains experience less wear, which significantly reduces maintenance costs.

Higher Speed: They can reach speeds of over 600 km/h, considerably reducing travel times compared to conventional trains and even airplanes on short routes.

Energy Efficiency: By eliminating mechanical friction, less energy is required to maintain speed and movement.

Noise Reduction: The absence of physical contact with the tracks minimizes vibrations and noise generated during travel.

Less Maintenance: The lack of moving parts in the propulsion system minimizes the need for repairs and prolongs the life of components.

Magnetic Braking Systems

Magnets also play a crucial role in the braking systems of trains and other transportation vehicles. Magnetic brakes, or induction brakes, use magnetic fields to create resistance and decelerate the vehicle smoothly and efficiently.

Advantages of Magnetic Brakes

Improved Safety and Control: They allow for more precise control over deceleration, increasing safety in emergency situations.

Reduced Mechanical Failures: Because there is no physical contact, these systems have a longer lifespan and require less maintenance.

Quiet Operation: Less noise compared to traditional braking systems.

Future of Magnetic Levitation

In the future, if we manage to control nuclear fusion, one of the most revolutionary applications of magnetic levitation could be plasma levitation. This breakthrough could transform energy production and open up new possibilities in space exploration and industrial technology.

Magnetic levitation represents a technological leap in the efficiency of transportation and industry. With the continued development of new magnetic materials and systems, Maglev could play a key role in urban mobility, sustainable development and innovation in energy production.