Magnetic Palletizers in the Canning Industry

Globalization and the speed at which the canning industry moves have generated great changes in logistics needs. Companies that want to lead in their respective fields are constantly looking for ways to improve. That is why they incorporate magnetic palletizers in their manufacturing line, as it is a sure way to obtain optimal and efficient performance in the transport of canned goods.

In an industrial panorama marked by constant technological advances, magnetic palletizers are redefining the way in which transport is carried out in production. Spain continues to be a world leader in the canning sector, but it is essential to continue innovating and adapting to new habits to maintain leadership in the packaging and handling of canned goods. This type of magnetic transport helps improve efficiency, precision and consistency in handling and transport processes.

What is a Magnetic Palletizer?

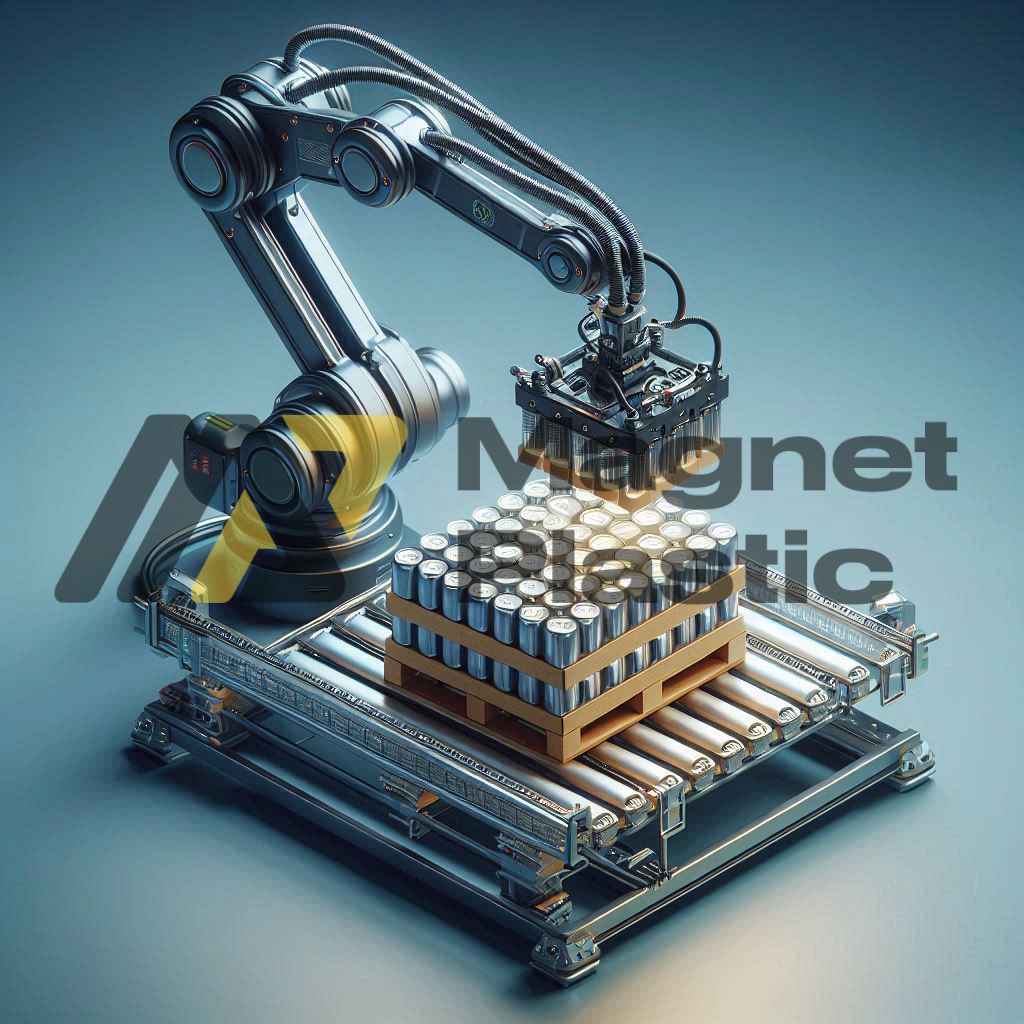

The magnetic palletizer is a magnet used for the transport of packaging with a metal lid. This is a magnetic system designed specifically for the handling and transport of containers and preserves. With palletizing magnets, it is possible to package cans, aerosols and glass jars with steel lids in a single movement.

The magnetic system does not require a constant power supply, making it an efficient and economical option. They are ideal for coupling to a robotic arm and facilitate packaging and unpacking in automated processes, reducing manual effort and improving productivity.

Applications in the Canning Industry

Magnetic palletizers are specially designed to increase production and reduce possible damage to products. It is a reliable and safe method for automated processes.

This type of magnetic transport is the most effective, fast and safe system for the transport and processing of fish and seafood. It is an ideal means for transporting any type of metal can, such as tuna, sardines and mussels.

Furthermore, it is a system widely used in the transport of canned fruit and vegetables in glass containers with metal lids, as well as in canned meat, legumes and vegetables.

Thanks to their great attraction force, these magnetic conveyors can move large loads regardless of the shape and dimensions of the product, guaranteeing safe and efficient handling.

Characteristics of MagnetPlastic Magnetic Palletizers

MagnetPlastic magnetic palletizers generate a great holding force thanks to Neodymium magnets. For the supply of these products, an individualized study is carried out in each case, in order to optimize the processes with the lowest weight and greatest efficiency.

The magnetic force is adjusted according to the type of container: full, empty, can or glass container. They incorporate pneumatic pistons that activate the internal magnets, allowing the magnetic force to be activated or deactivated at the bottom of the unit. In addition, the configuration of the anchors is designed in conjunction with the client to adapt the equipment to the installation.

They can be supplied in various formats, with different pneumatic pistons and dimensions adjusted to the process and type of cans to be transported. Their robust and efficient design guarantees intense and uninterrupted work, since, thanks to the permanent magnets, they do not require maintenance.

Conclusion

Magnetic palletizers have revolutionized the canning industry by offering an efficient and safe solution for the transport of metal and glass containers. Their ability to handle large volumes accurately, without the need for constant energy or frequent maintenance, makes them an essential investment for companies in the sector.

MagnetPlastic continues to innovate in this field, ensuring that its magnetic systems are synonymous with quality, efficiency and safety in canning production. The implementation of this equipment in manufacturing lines guarantees an improvement in the logistics and operational performance of companies.