Magnetic Separators: Efficiency in Action

Magnetic separators are ingenious devices that play an essential role in separating ferrous materials from product streams, providing efficiency and cleanliness in various industrial processes. In this article, we will explore the operation of magnetic separators and their versatile applications in industry, highlighting their contribution to process improvement and the quality of final products.

Operation of Magnetic Separators: The Applied Force of Magnetism

The operation of magnetic separators is based on the fundamental principle of magnetic attraction. These devices incorporate powerful magnets that generate intense magnetic fields. When materials pass through these fields, ferrous particles are attracted to the magnets, separating from the product flow. This process allows for the efficient removal of ferrous contaminants, enhancing the purity of final products.

Types of Magnetic Separators and Their Applications

Magnetic Pulleys or Rollers:

Applications: Used in conveyor belts for the extraction of ferrous contaminants in the mining industry and material recovery.

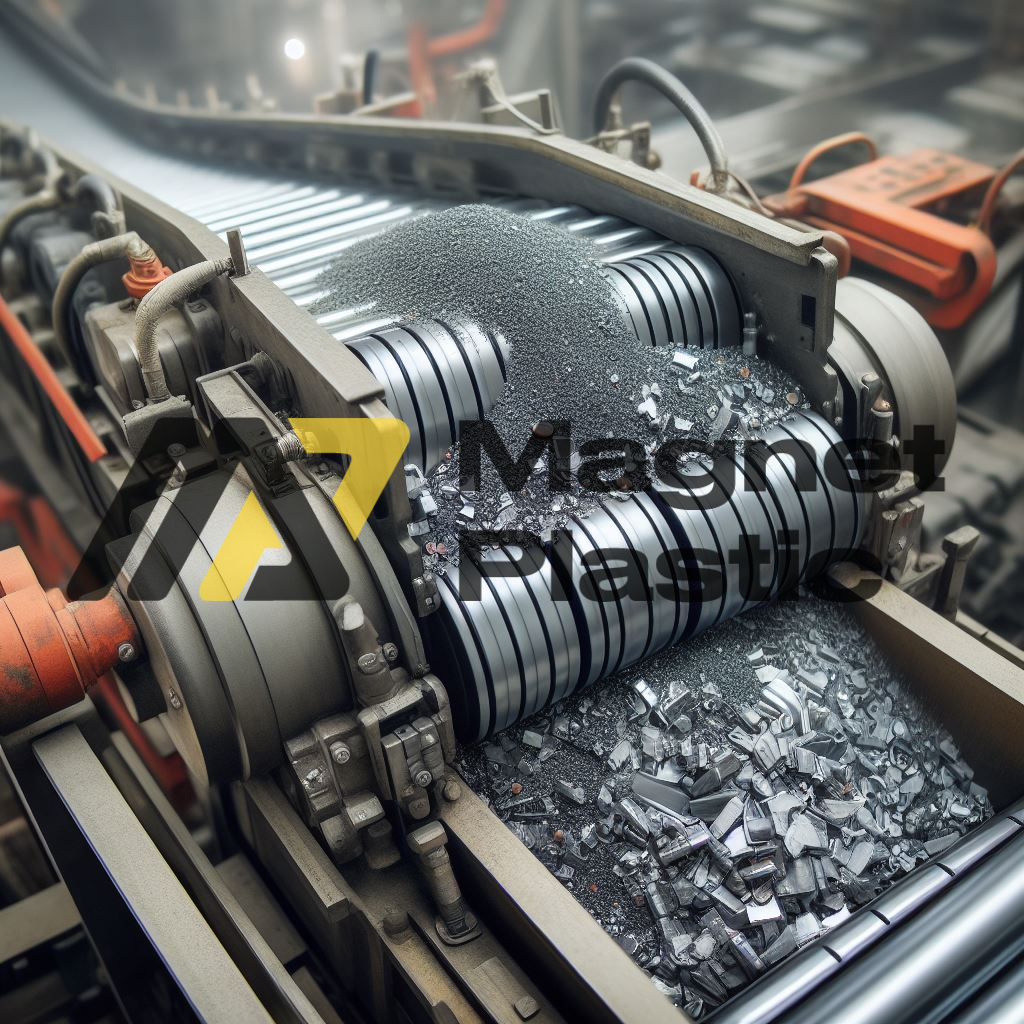

Magnetic Drums:

Applications: Efficient in separating ferrous particles in the food and recycling industries.

Magnetic Grates:

Applications: Employed in protecting equipment and machinery in the manufacture of plastics, ceramics, and chemicals.

Magnetic Plates:

Applications: Used in hoppers and ducts to capture ferrous contaminants in manufacturing processes.

Key Advantages in Industry

Product Quality Improvement:

The efficient removal of ferrous contaminants ensures the quality of final products, especially in sectors such as food and pharmaceuticals.

Equipment Protection:

Prevents damage to machinery and equipment by capturing ferrous particles before they enter critical processes.

Compliance with Regulations and Standards:

Helps meet regulations and quality standards by ensuring product purity.

Continuous Innovation and Future

Research in the field of magnetic separators focuses on improving efficiency and adaptability. Advances in magnetic materials and innovative designs are leading to more effective and customized solutions for various industrial needs.

In conclusion, magnetic separators play a crucial role in improving industrial processes by ensuring product cleanliness and purity. Their operation based on magnetic principles, combined with a variety of specialized designs, makes them indispensable tools in sectors ranging from mining to manufacturing.