Magnetic Tube: Uses and Applications

Industrial Solution for Product Purity

In modern industry, product purity is a critical requirement, especially in sectors such as food processing, pharmaceuticals, and materials recycling. To meet these high standards, various magnetic separation solutions have been developed—among them, the magnetic tube separator stands out. This compact yet highly efficient device is designed to extract ferrous contaminants from pneumatic or gravity-fed process lines, ensuring the final product’s integrity and the safety of the entire process.

How the Tubular Separator Works

The magnetic tube separator is typically installed in pipelines that transport dry, free-flowing products such as food powders or plastic granules. Its design allows material to flow directly over a powerful magnet made from ferrite or rare earth elements (neodymium), ensuring the efficient removal of unwanted metal particles. These magnets are strategically placed for easy access during cleaning operations—an essential routine to maintain system efficiency.

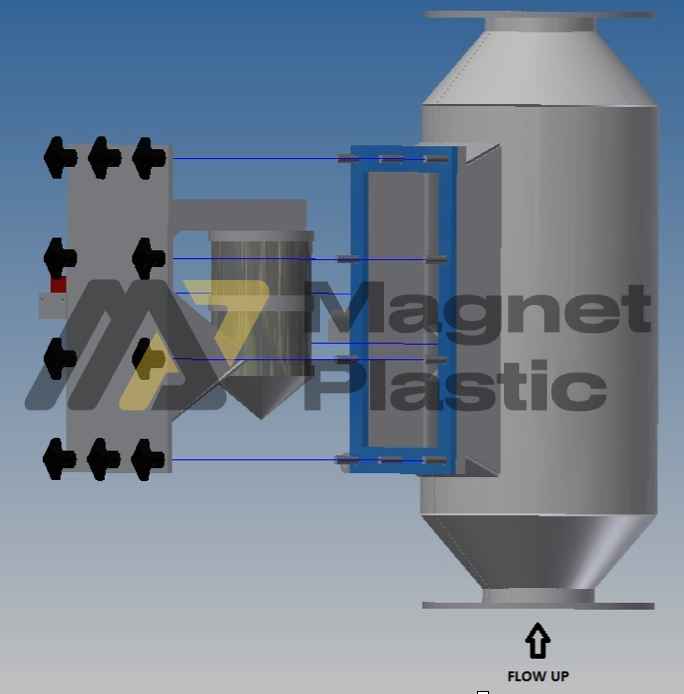

Versatility in Design and Installation

One of the main advantages of this type of separator is its versatility. It can be installed in horizontal or vertical positions, with upward or downward product flow, depending on system requirements. To ensure optimal performance, several key factors must be considered during setup: pipeline size and pressure, product particle size, system temperature, and capacity in tons per hour.

Optimal Flow with Minimal Turbulence

Internally, the separator features deflectors that guide the material evenly over the magnet, creating minimal turbulence and preventing blockages. This internal design promotes a steady, continuous product flow while maximizing contact with the magnetic field, enhancing the separation efficiency.

Key Features

- Easy to install and clean

- Consistent high performance

- Ideal for free-flowing powders and granules (plastics, food ingredients)

- Hygienic quick-release sealed door

Technical Specifications

- Available with ferrite or high-intensity neodymium magnets

- Fits pipelines from 50 mm to 350 mm in diameter

- Round door version supports up to 0.5 bar pressure

- Flat door version supports up to 2 bar pressure

- Constructed entirely of stainless steel for durability and sanitary compliance

Applications and Benefits in Tight Spaces

When space constraints prevent the use of larger magnetic drawer systems, the tubular separator is the perfect alternative. It connects easily to flexible ducts and can be installed between loading units and vacuum loaders, providing permanent magnetic protection without disrupting the product flow.

Conclusion

In summary, the magnetic tube separator is a practical, durable, and high-performance solution for keeping industrial processes free of ferrous contamination. Its compact design, high efficiency, and ease of maintenance make it an essential tool for ensuring purer products and safer operations.