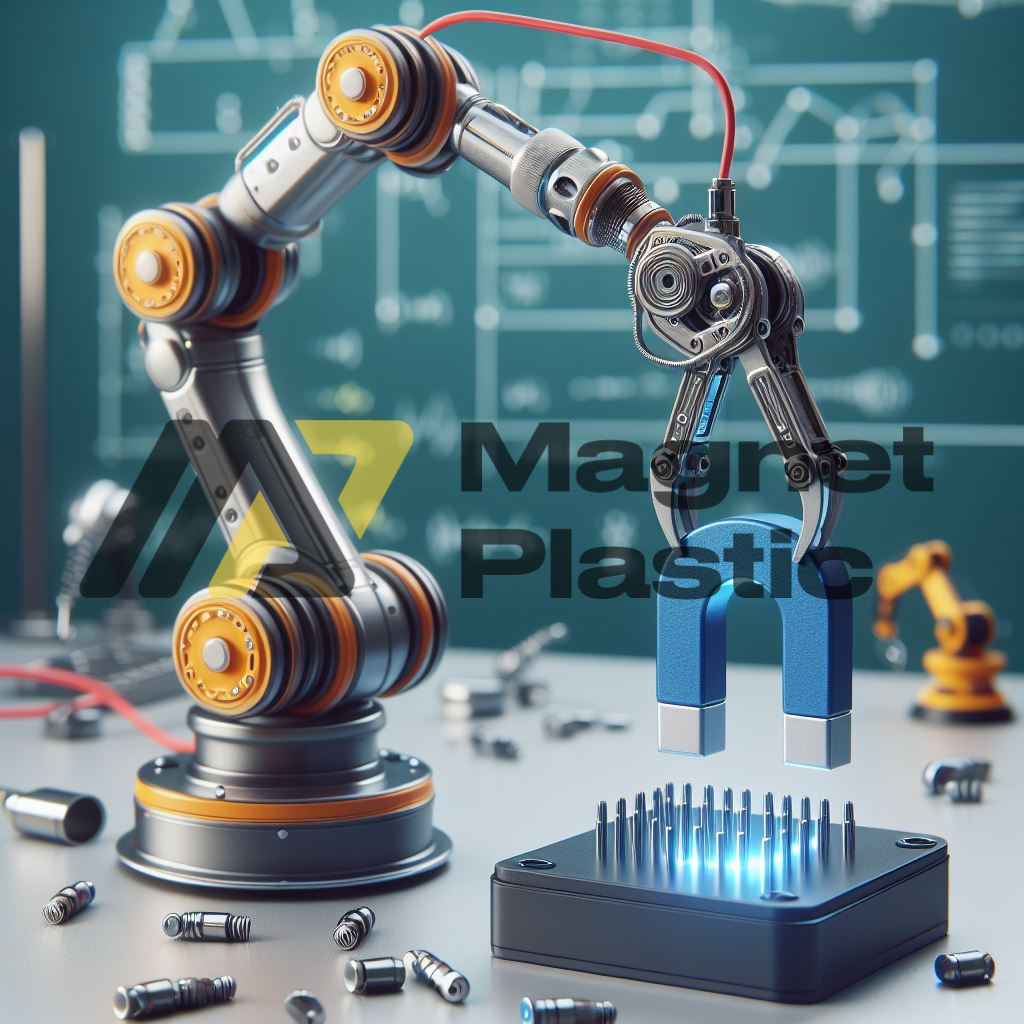

Magnets in Handling and Robotics

The integration of magnets in the fields of handling and robotics has marked a significant advancement in recent years, thanks to the numerous advantages they offer. These magnetic devices have become essential tools for transporting and manipulating objects, especially in environments with limited space and extreme precision requirements.

Variety of Magnets for Handling and Robotics

In the handling and robotics industry, different types of magnets are employed, notably permanent magnets and electromagnets.

- Permanent Magnets: These generate a constant magnetic field, making them ideal for applications that require stable magnetic force without polarity changes. Permanent magnets are used in door locking systems, motor brakes, and various industrial sensors.

- Electromagnets: These generate a magnetic field when an electric current flows through them. Their ability to modulate the magnetic field’s intensity makes them indispensable for handling objects with varying characteristics and weights in automated production environments.

Strategic Applications in Handling and Robotics

Magnets have revolutionized the systems for transporting and manipulating objects in industry. Magnetic-based transport systems enable the movement of objects through magnetic force, optimizing the handling of parts on production lines, product sorting in warehouses, and logistics operations for loading and unloading.

In robotics, the precision and speed of object manipulation have been greatly enhanced by magnets. Robots equipped with this technology are crucial in the automotive industry for handling parts on assembly lines and in the electronics industry for manufacturing circuits and components.

Automation and Efficiency in Production

The constant evolution in robotics has led to the automation of numerous production processes, improving quality and efficiency in final output. In environments such as automotive production lines, the combination of human skills and robotic capabilities optimizes costs, ensures quality standards, and reduces working times.

Process automation is a key strategy for business competitiveness, with magnets playing a fundamental role. Their ability to handle heavy loads, generate signals for process control, and contribute to safe and efficient operations makes them indispensable allies in the handling and robotics industry of the 21st century.