Magnets in Textile Machinery: Innovation and Efficiency in the Industry

The textile industry is a sector in which precision, efficiency, and final product quality are essential to remain competitive. In this context, magnets have become key components within modern textile machinery, offering technological solutions that range from equipment protection and process optimization to enhanced quality control. Their growing use demonstrates that magnetism is a strategic ally for an industry increasingly oriented toward automation and high performance.

1. Machinery Protection and Safety

One of the most important uses of magnets in the textile industry is the separation of metallic particles. During the handling of natural or synthetic fibers, it is common to encounter metal fragments such as nails, broken needles, or small parts that detach from machines. The integration of permanent magnets and electromagnets in conveyors, hoppers, or magnetic filters helps capture these elements before they reach sensitive machine components. This preventive measure not only avoids costly damage but also reduces the risk of defects in fabrics, ensuring a safer and more consistent final product.

2. Material Holding and Transport

Magnets also play a crucial role in the holding and manipulation of materials within textile machinery. In automatic cutting machines or assembly systems, they help secure metal components or fabric layers with precision, preventing unwanted movement that could affect cutting accuracy or alignment. Similarly, magnetic conveyors are used to move metal parts without direct mechanical contact, which reduces wear, minimizes vibrations, and improves the energy efficiency of the production line.

3. Tension Control and Alignment

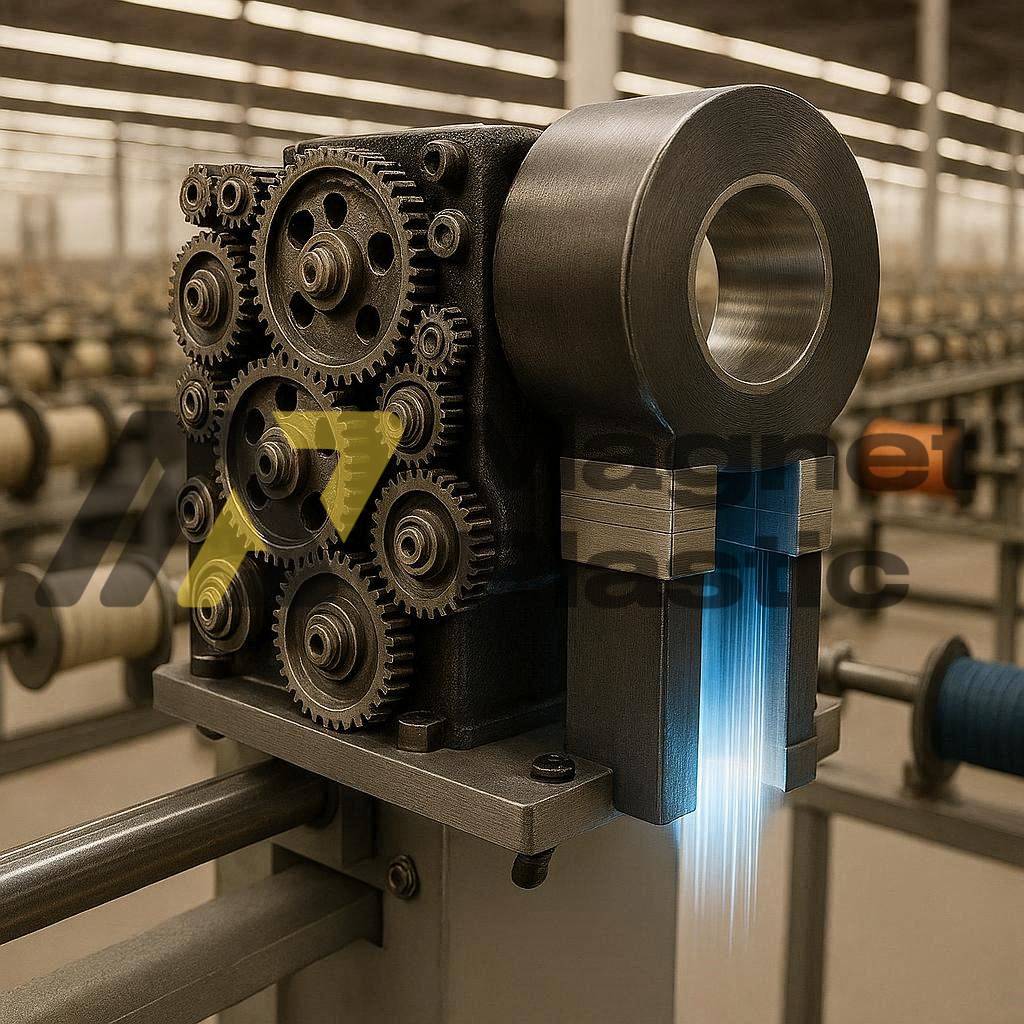

Magnetism also provides significant advantages in controlling thread and fabric. Certain rollers, brakes, and guides use magnetic fields to maintain the correct tension or ensure proper alignment of the material during weaving, printing, or finishing. This technology is particularly beneficial for fine, elastic, or delicate fabrics, where even slight deviations can compromise the uniformity and quality of the final result.

4. Cleaning and Maintenance

In preventive maintenance, magnets play an essential role. In workshops and production lines, magnetic collectors help capture metal dust, shavings, and wear residues generated by machine operation. Keeping equipment clean and free of contaminating particles prolongs its lifespan, reduces the frequency of breakdowns, and minimizes unplanned stoppages that negatively affect productivity.

5. Advanced Innovations and Applications

Technological advancements have led to new magnetic applications in the textile sector. Among the most notable are magnetic levitation rollers, which reduce friction and enable faster, smoother fabric movement. Magnetic sensors capable of detecting the real-time position of threads or materials also stand out, automatically adjusting machine parameters to ensure maximum precision and repeatability. Additionally, hybrid systems combining magnetism with mechanical or pneumatic technologies are emerging to tackle more complex weaving and finishing processes.

Conclusion

Magnets have become indispensable tools in modern textile machinery. Their ability to protect equipment, streamline processes, and improve final product quality makes them a key element in the sector’s competitiveness. As magnetic technologies continue to advance, their integration will enable textile companies to operate more efficiently, lower maintenance costs, and offer higher-value products. Without a doubt, magnetism will continue to guide the textile industry toward greater innovation, productivity, and excellence.