MagnetPlastic

Manufacturing of Magnets and

Magnetic Systems

.ISO 9001:2015 ISO 14001:2015

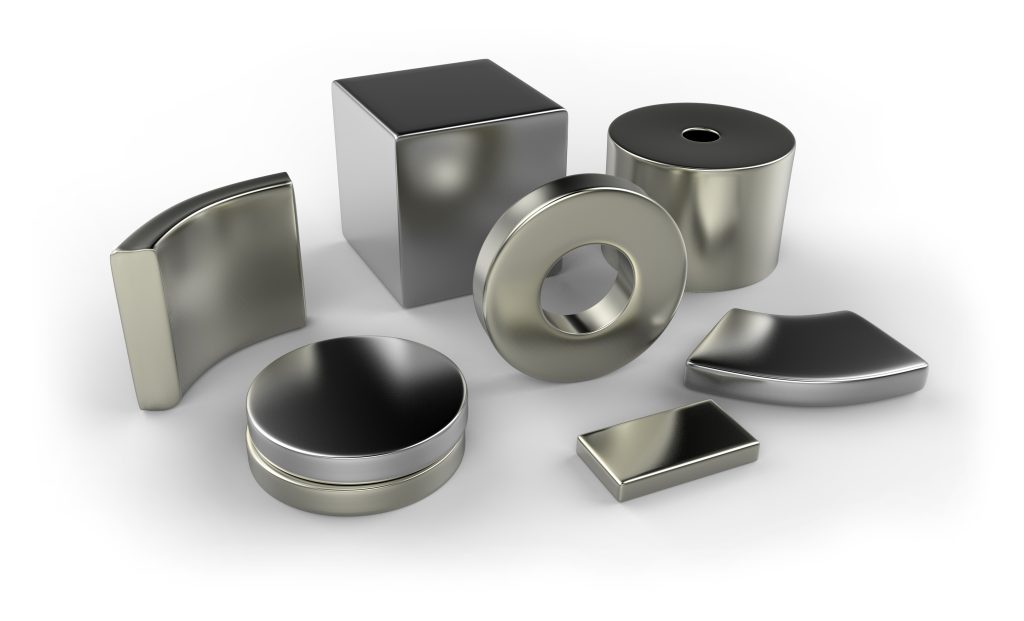

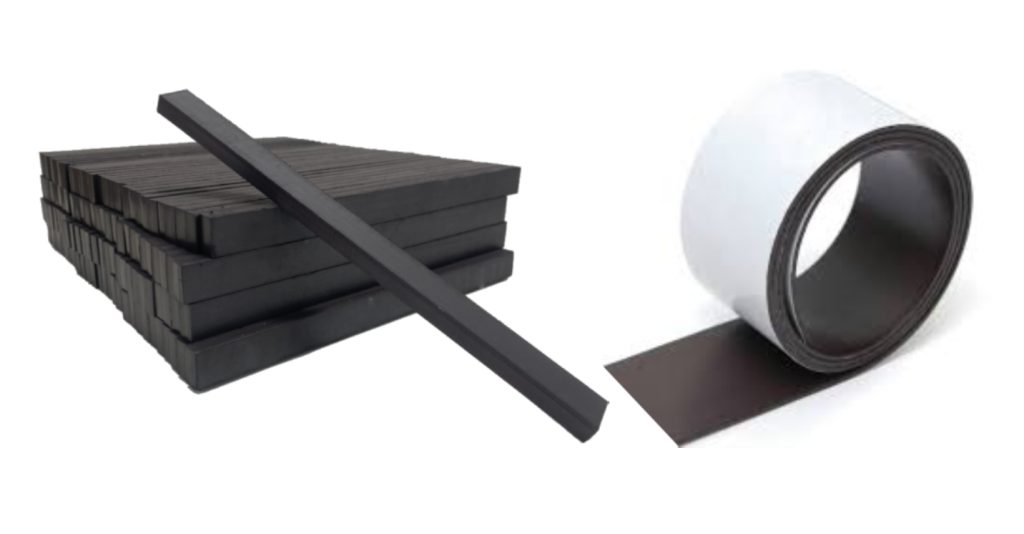

MAGNETS

Magnets are materials capable of generating a magnetic field, attracting ferromagnetic metals such as iron, nickel and cobalt. There are several types of magnets, including permanent magnets, which maintain their magnetism without the need for external energy, and electromagnetic magnets, which require an electric current to generate a magnetic field. Among the best-known permanent magnets are neodymium magnets, which stand out for their high magnetic strength and compact size.

Magnets have applications in a wide range of industries and devices. In electronics, they are used in hard drives, speakers, and electric motors. In the medical sector, they are essential in equipment such as magnetic resonance imaging (MRI) machines.

The versatility and efficiency of magnets make them essential components for technological and scientific development, as well as for the optimization of industrial processes and the improvement of everyday products.

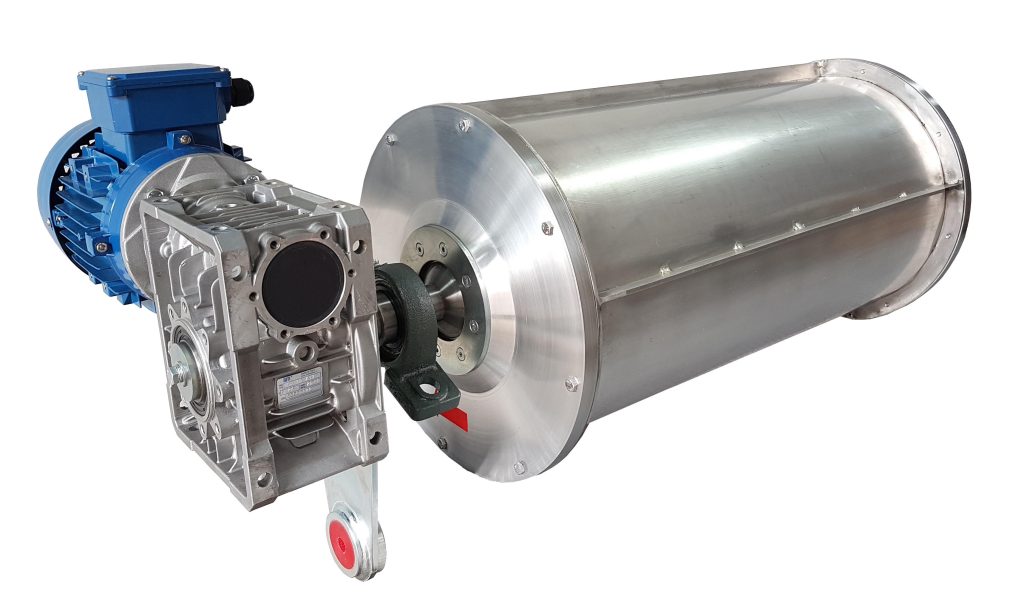

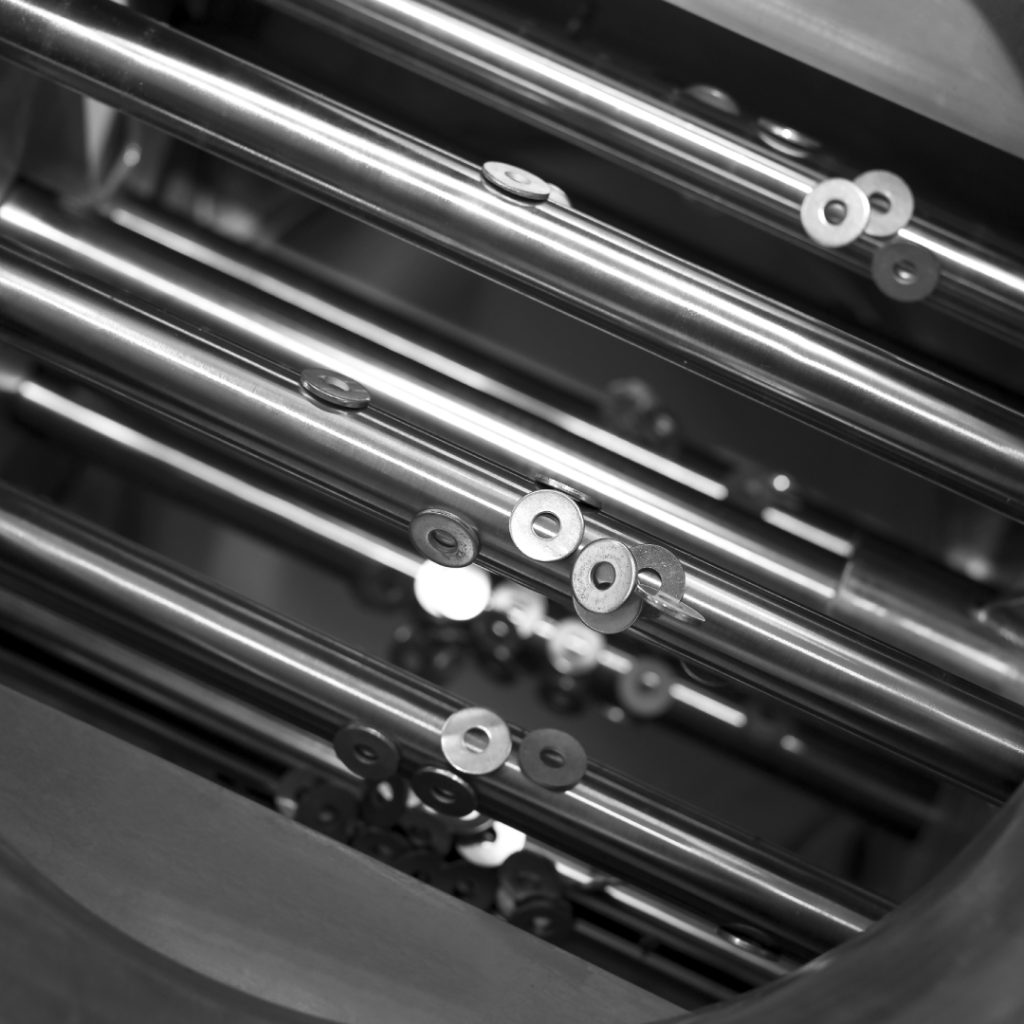

MAGNETIC SEPARATION

Magnetic separation systems are crucial tools in multiple industries to remove ferromagnetic materials from various mixtures. They use high-intensity magnets to attract and retain magnetic particles, effectively separating them from non-magnetic materials. These systems are widely applied in sectors such as mining, recycling, food and mineral processing. Its efficiency lies in the ability to capture ferrous particles quickly and accurately, thus optimizing industrial processes.

By improving final product purity and reducing ferrous contamination, these systems not only increase product quality, but also reduce operating costs and minimize equipment wear and tear. This, in turn, extends the useful life of the machinery and contributes to more efficient and sustainable production. The implementation of magnetic separation systems is, therefore, a strategic investment for any industry seeking to improve its production processes and guarantee the quality of its products.

"Our goal is customer satisfaction."

At MagnetPlastic, we can guarantee the quality of all our products.

We guarantee stability in the production of our products, ensuring quality and supply. Customized solutions fully optimized: high-tech magnetic materials, magnetic systems, and thermoplastic injection. Experience, knowledge, and technical implementation equal efficiency.

Customized solutions for all sectors

Who we are

MagnetPlastic is an international company focused on providing its customers with magnets, industrial magnetic systems, thermoplastic injections, and injection molds.

After 20 years in the magnetism and injection sector, MagnetPlastic was born to stand alongside the customer, with a clear vocation for service, advising and providing the most optimal and efficient solutions. At MagnetPlastic, we provide thorough and personalized follow-up for each project and accompany our clients in all phases of the magnet acquisition, plastic injection projects, and mold processes. Our extensive experience in the industrial sector and product development provides a significant advantage for our clients. Customer satisfaction is our goal.

Customer Service

Contact Us

If you need information or advice for any type of magnetic or plastic application, please fill out the following form. We will contact you within 48 hours.